VEVOR Electric Pushed Hydraulic Pumps

페이지 정보

본문

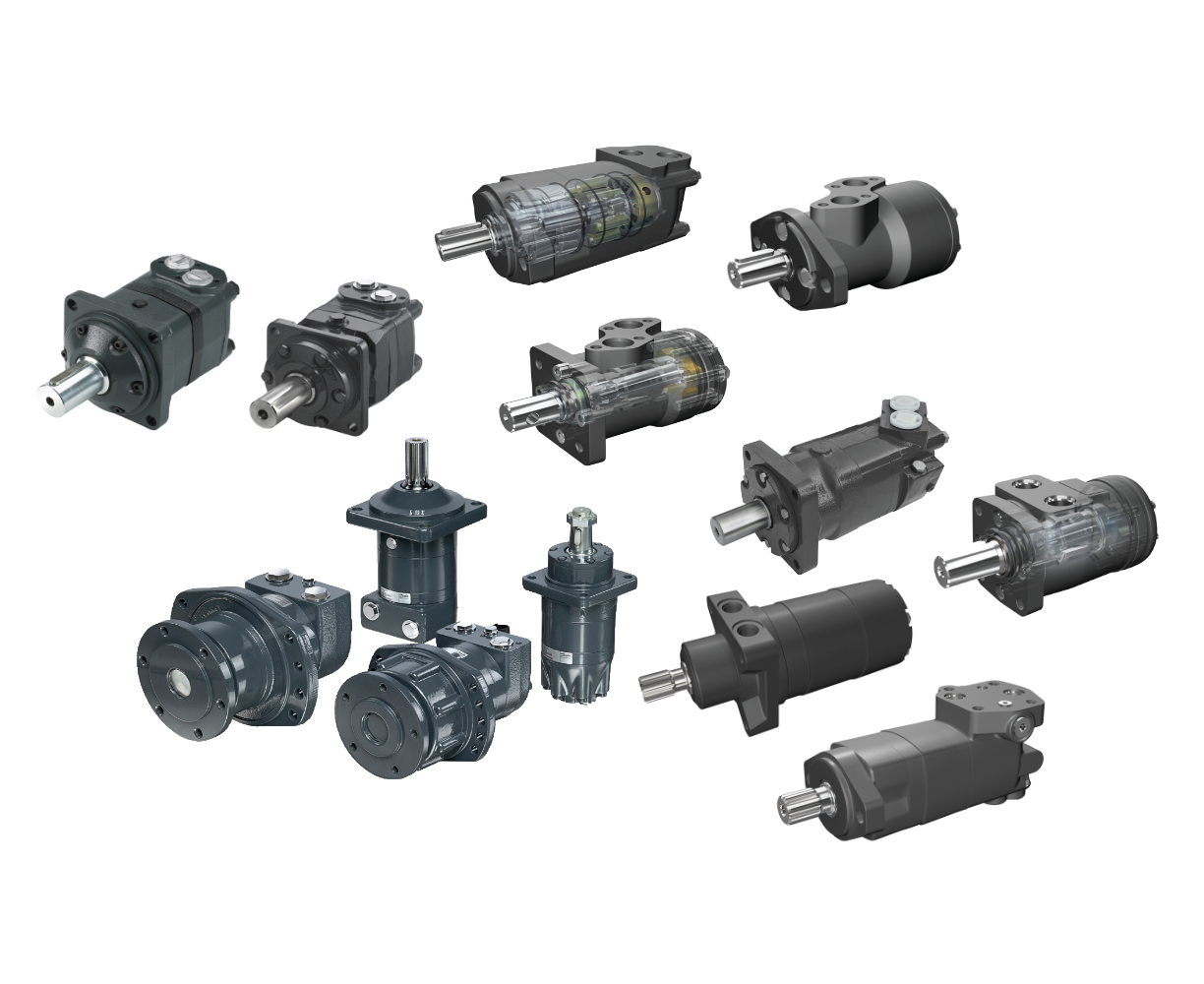

VEVOR electric driven hydraulic pumps are designed to supply highly effective forces behind hydraulic work and are thus ideally suited to industries that require lifting, urgent or bending. It may both be heavy machinery dealing with, conducting easy upkeep, or just powering hydraulic tools. A hydraulic pump with an electric motor presents steady force so you may get the work done efficiently. As we speak we come to the purpose in our "orbital steering saga" (do try Half 1 and Part 2 if you have not already) where we glance on the orbital section in additional detail. Essential and very useful, because low-speed excessive-torque orbital motors are ubiquitous, and understanding the small print of how they work makes you a greater tech! Our motors are compatible with quite a lot of brands, together with Sauer Danfoss, Eaton Char-Lynn (S sequence, 2000), John Deere, JLG, Bobcat, CASE, Gehl, New Holland, Parker, White (500 series), Skyjack, and Volvo. They are suitable for a variety of equipment types reminiscent of excavators, cranes, bulldozers, scissor lifts, loaders, growth lifts, and more. Rated torque: The torque value a hydraulic motor can maintain underneath commonplace operating situations.

Hydraulic motors are mechanical actuators that convert hydraulic stress and move into torque and angular displacement. The motors are sometimes one in every of the most important components of a hydraulic system and ensuring that you choose the right one is essential to make sure your hydraulic system is operating effectively. All our merchandise are of the best high quality and are solely designed that can assist you to realize your goals. For some other hydraulic accessories, you’ll be capable of finding the perfect tools to your job amongst our vary, so please be at liberty to proceed to browse our website. Most pressure is 276 bar (4,000 psi). Hydraulic motors are supposed for top torque and low velocity applications where it’s undesirable or impractical to make use of electric motors. This may very well be because high voltage cables can’t be used or because mobility is needed. Hydraulic orbital motors are used in two conditions: static functions found in business, mining and agriculture, and cell, vehicular functions like these in agriculture, forestry, construction, landscaping and logistics. An orbital motor often consists of a fixed or transferring cycloidal curve and a slider. When the cycloid curve rotates, the slider will make a linear movement as the curve adjustments. Because the form of the cycloidal curve is very common, the velocity and acceleration of the slider may be managed very precisely.

These heavy-obligation hydraulic orbital motors incorporate tapered roller bearings engineered for increased facet load capability. That ensures they'll handle the forces skilled in wheel motor and positioning applications. Additionally they use a heavy-responsibility drive hyperlink design that permits them to handle spikes in strain and torque. In addition, to cope with the arduous circumstances discovered on job websites and in fields, they are available with slinger seals that stop materials building up around shafts and discovering its manner inside. Whereas they have certain disadvantages such because the necessity for clear hydraulic programs and potential noise issues, ongoing technological advances are steadily mitigating these drawbacks. With a watch to the long run, we can anticipate the continued evolution of hydraulic motors, promising additional advantages to numerous industries and applications. The first goal of this undertaking is to help the general public to learn some thrilling and necessary details about electricity and magnetism. Our Website follows all legal requirements to guard your privateness. Go to our Privacy Coverage web page.The Cookies Assertion is part of our Privateness Coverage. The information contained on this webpage is for common information functions only. This webpage does not use any proprietary information. Go to our Editorial word.

It will run with continuous stress from 250 to 3,000psi however to maximise efficiency should not be subjected to more than 2,500 psi. As well as, at 2,500 psi stream needs to be between 8 and 12 gpm. Manufacturers like Impro Fluidtek publish performance charts for each Orbital motor applications motor they produce. Once torque, speed, pressure and circulation are known, seek the advice of these charts to pick the best motor on your utility. A hydraulic orbital motor that’s sized appropriately for the applying will ship 1000's of hours of service with solely minimal maintenance. Choosing the best motor requires careful evaluation of the appliance surroundings and pump system (if known or previously established). To make sure all elements are taken into consideration, contact us to arrange a overview with a technical specialist earlier than finalizing your choice.

Motors uncovered to water could rust, and contaminants can result in leakage, cracking, or undesirable vibrations. What Approvals and Certifications are Required? Motors might have to satisfy various standards, including worldwide, workshop, or engineering approvals. Contemplating these requirements is crucial to avoid safety points and ensure compliance with engineering requirements. Proper upkeep is essential to optimal motor efficiency. Beneath are concerns for sustaining hydraulic motors. Hydraulic motors play an important role in the engineering and automation of many methods in our on a regular basis lives. Though a few of them are complicated, most of those motors use simple working principles which are easy to grasp and are person-pleasant.

- 이전글Guide To Near Me Psychiatrist: The Intermediate Guide The Steps To Near Me Psychiatrist 25.03.04

- 다음글Three Greatest Moments In Buying A Driving License Experiences History 25.03.04

댓글목록

등록된 댓글이 없습니다.